In today's competitive marketplace, identifying the best manufacturers is crucial for businesses aiming to excel in quality and compliance. According to a recent report by the International Organization for Standardization (ISO), manufacturers who adhere to established industry production standards not only improve operational efficiency but also enhance product reliability and customer satisfaction. More than 75% of consumers express greater trust in brands that maintain compliance with recognized standards, highlighting the importance of due diligence in manufacturing partnerships. By analyzing compliance data, businesses can uncover insights that reveal manufacturers' commitment to quality and sustainability practices. This blog will delve into the intricacies of assessing industry production standards, illustrating how a meticulous approach can lead to informed decisions and foster long-term success in the supply chain.

When evaluating potential manufacturers, understanding industry production standards and compliance data is crucial to making informed decisions. Best practices for assessing these standards can significantly enhance the quality and reliability of your supply chain. One effective approach is to conduct thorough research on industry benchmarks. Familiarize yourself with the specific standards relevant to your sector, as these guidelines often serve as a foundation for evaluating production quality.

In addition, leverage compliance data to assess a manufacturer's track record. Regular audits and certifications can provide insights into their commitment to maintaining high standards. Look for manufacturers that have consistent compliance with relevant regulations and industry expectations. This data can often be found in public records or through industry trade associations, which offers a transparent view of the manufacturer’s reliability.

Tip: Create a checklist that includes key production standards and compliance criteria tailored to your industry. This will help streamline the assessment process and ensure you cover all necessary factors. Moreover, consider conducting interviews with suppliers to gain qualitative insights into their production processes and adherence to standards. These interactions can reveal a lot about their operational philosophy and commitment to quality.

To identify the best manufacturers, analyzing compliance metrics is crucial. Key compliance metrics include adherence to industry regulations, quality management systems, and environmental standards. For instance, a 2021 report by the International Organization for Standardization (ISO) indicated that 75% of manufacturers with certified quality management systems achieved higher customer satisfaction and lower defect rates. This statistic highlights the importance of ISO 9001 certification as a benchmark for evaluating production standards.

Another critical compliance metric is the adherence to environmental regulations, which can significantly impact a manufacturer's reputation and operational viability. According to a 2022 study by the Environmental Protection Agency (EPA), companies that comply with environmental standards not only reduce their ecological footprint but also improve their efficiency by up to 30%. This efficiency often translates into cost savings and enhanced competitiveness. By focusing on these key compliance metrics, businesses can distinguish top manufacturers who not only meet industry production standards but also contribute positively to sustainable practices.

The Role of Technology in Production Standards

In today's manufacturing landscape, technology plays a pivotal role in establishing and adhering to production standards. As industries continue to embrace Industry 4.0, intelligent automation and data analytics are reshaping how compliance data is monitored and evaluated. Reports indicate that companies leveraging advanced technologies enhance their production efficiency by up to 30%, ultimately leading to improved product quality and reliability. This trend is particularly evident in sectors such as battery manufacturing, where rigorous testing and innovative material sourcing are crucial for product development.

Tips: To identify the best manufacturers, utilize compliance platforms that provide real-time insights into production standards. This allows organizations to preemptively address any gaps in compliance and select partners with proven records of adherence to industry norms.

Furthermore, the rise of generative AI represents another significant advancement in production technology. By automating complex processes and aiding skilled workers, generative AI can potentially add trillions to the global economy. It also facilitates a culture of accountability, essential for maintaining high standards in production. Harnessing these technologies can enable manufacturers to remain competitive while consistently meeting or exceeding compliance requirements.

Tips: Foster a culture of innovation and peer training within your organization to fully capitalize on new technological advancements. Creating an environment where employees are encouraged to explore and implement technology-driven solutions can lead to remarkable increases in productivity and compliance adherence.

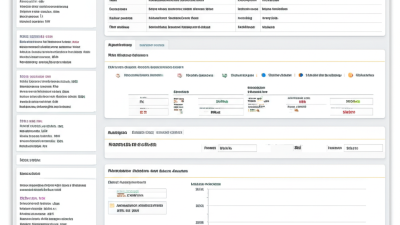

| Criteria | Description | Compliance Rate (%) | Industry Standard Reference | Technology Utilized |

|---|---|---|---|---|

| Production Efficiency | Measures output in relation to input resources | 85 | ISO 9001 | Automation Systems |

| Quality Control | Ensures products meet specific quality standards | 90 | Six Sigma | Data Analytics |

| Regulatory Compliance | Adherence to industry regulations and laws | 95 | OSHA Standards | Compliance Management Software |

| Sustainability Practices | Integration of eco-friendly processes | 88 | ISO 14001 | Energy Management Systems |

| Employee Safety Standards | Measures the safety protocols in place for workers | 92 | ISO 45001 | Safety Management Software |

In today's competitive landscape, understanding compliance data is crucial for identifying the best manufacturers across various industries. As organizations face increased regulatory scrutiny, leveraging data analytics has emerged as a key strategy in evaluating compliance standards. Notably, recent surveys indicate that a significant percentage of companies are utilizing data analytics to assess compliance risks, turning raw data into actionable insights that help reinforce their operational foundations.

Effective analysis starts with mastering data management. By systematically organizing and accessing data related to customers, suppliers, and production practices, manufacturers can uncover trends that indicate compliance health. This proactive approach not only aids in identifying potential risks but also supports continuous improvement initiatives. Furthermore, aligning analytics with industry-specific standards allows manufacturers to benchmark their performance and ensure they meet or exceed regulatory requirements. Ultimately, by integrating strong analytics into their compliance programs, companies are better equipped to navigate complex regulatory landscapes while building trust with stakeholders.

This bar chart illustrates the compliance rates of manufacturers across various industries based on production standards. The data reflects the percentage of manufacturers meeting compliance requirements in sectors such as electronics, automotive, pharmaceuticals, and food processing.

In an era of rapidly evolving manufacturing processes, understanding future trends in manufacturing standards and compliance analysis is crucial for identifying the best manufacturers. As the global market becomes increasingly competitive, manufacturers are expected to adapt to more stringent regulations and adopt innovative practices that prioritize sustainability and safety. Industry 4.0 technologies, such as IoT and AI, are set to revolutionize how compliance data is collected and analyzed, allowing for real-time monitoring and quicker responses to any non-compliance issues.

Tip: Embrace technology to streamline compliance processes. Utilizing data analytics tools can help manufacturers identify potential risks and inefficiencies in their operations, ensuring they remain ahead of regulatory changes.

Another significant trend is the growing emphasis on environmental and social governance (ESG) standards. Consumers and investors are demanding transparency regarding ethical practices, prompting manufacturers to incorporate ESG metrics into their compliance analysis. This shift not only enhances brand reputation but also fosters long-term sustainability, making it easier to attract partnerships and investments.

Tip: Engage with stakeholders to gather feedback on your compliance and manufacturing standards. This engagement can provide valuable insights and help in refining your strategies to meet evolving expectations in the industry.